Product

SPECIFICATION

MACHINE CONFIGURATION:

- Automated container loading in

- 4/6 colors Modular offset machine

- UV Curing system

- Corona system or flame treatment unit

- Automated unloading, counting and restacking

MACHINE CONSISTS OF:

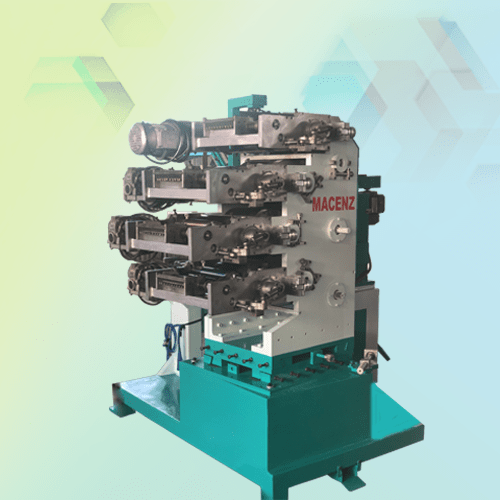

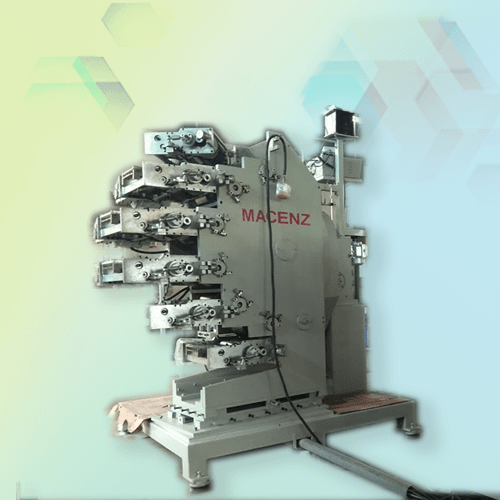

MACENZ DRY OFFSET PROCESS PRINTING MACHINE

Consisting of Two/Four/Six modular ink heads for each color. Each ink head consists of an ink duct with doctor arrangement, manually adjustable and ink in – feed system, Inking roller, Transfer roller, two oscillating rollers, Riding roller and form roller. All six ink heads are separately swing open for access to above components for wash – up. Structural plates of the assembly are powder coating plated for easy cleaning of ink stains and spills. The machine is designed for operating with two or four printing blankets. While printing smaller containers typically up to a diameter of 85mm, a 4 blanket system is recommended and this allows for higher machine speeds. While printing larger diameters where a larger print length is required, the machine has to be set – up for a two blanket system which will allow for a print length of up to 480mm while printing larger diameters, the machine speed will inherently be lower. The 2 blanket or 4 blanket configurations has to be specified at the time of ordering machine.

HEAVY DUTY EIGHT STOP INDEXING UNIT:

Designed for continue OHS high speed operation. The indexing unit houses an octagonal turret and container holding fixtures.An air ejection system is provided for container ejection.

BACKLESS GEAR:

For Good Results in Half – Tone Printing.

STRUCTURAL ASSEMBLY:

For mounting the offset unit and the indexing unit. The assembly allows for lateral and angular indexer positioning. The entire assembly is highly precise and it designed to support the indexer and offset unit in high speed operation at low vibration levels.

HIGH PERFORMANCE UNIVERSAL 4 – SCREW AUTO LOADER:

For high speed operation container feeding for all common sizes within the machine range is possible by a single device. A synchronized drive system ensures flawless container loading to match any operational speed. Mode of container feeding into the Machine is automatic through on autoloader

CONTROL PANEL:

For easy and immediate access to normal operating controls. The panel also displays the operating parameters, machine function status and machine speed for operator reference. AC drives are provided in the panel, for smooth running and easy controlling.

ON LINE FLAME TREATMENT SYSTEM:

This is required for Printing PP containers. The system consists of Burner or Electrical sparking unit and Mandrill rotating unit. This is Optional unit on the Machine. Unless the client gives a letter of indemnity against any accident to property or operating personal arising out of the uses of the Flame treatment system.

UV CURING SYSTEM:

We offer UV curing unit, this is designed for high speed UV curing’s. Our unit has a blower cooling system that reduces heat transmission to stock. It also exhausts ozone and hot air from the heat source and helps to keep cool printing shop. Moreover, our unit is equipped with digital hour meter that records the life of lamp. The lamp reflector of UV curing unit provides safe and easy cleaning. Medium pressure mercury vapour UV lamps 400 watts/inch can also be run at 250 watts/inch for low production speed if required Lamp reflector hinged for safety and easy cleaning, the system consists of a UV – A reduction source, this system cures printed containers on mandrels before ejection from the machine.

RE-STACKING UNIT:

This unit receives printed containers from the machine and generates a continuous stack of containers ejected from the machine, number counting and stack segmenting system is incorporated in this system.